Single platform laser cutting machine 6000W

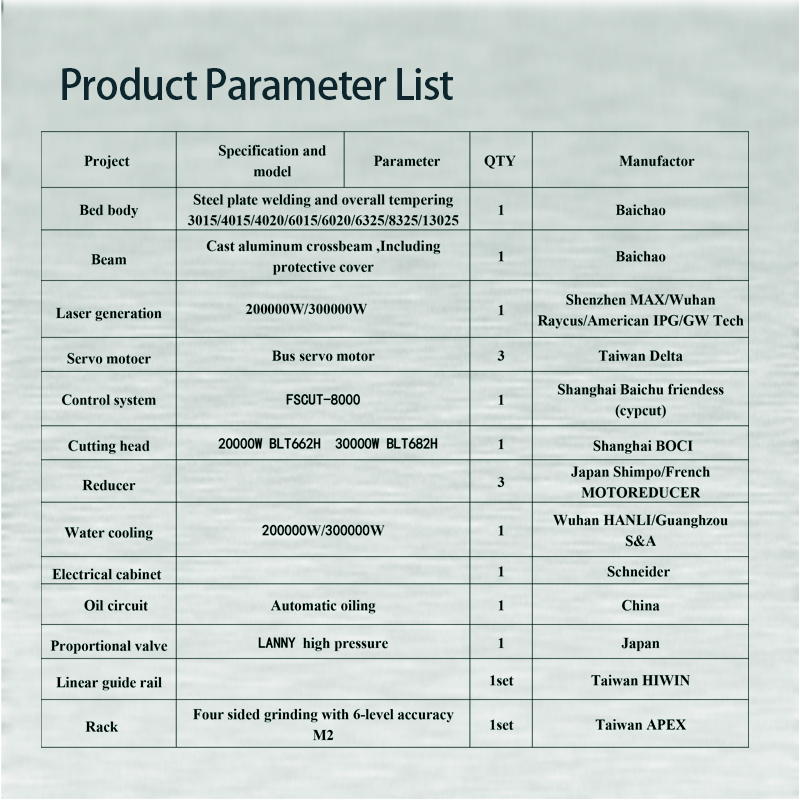

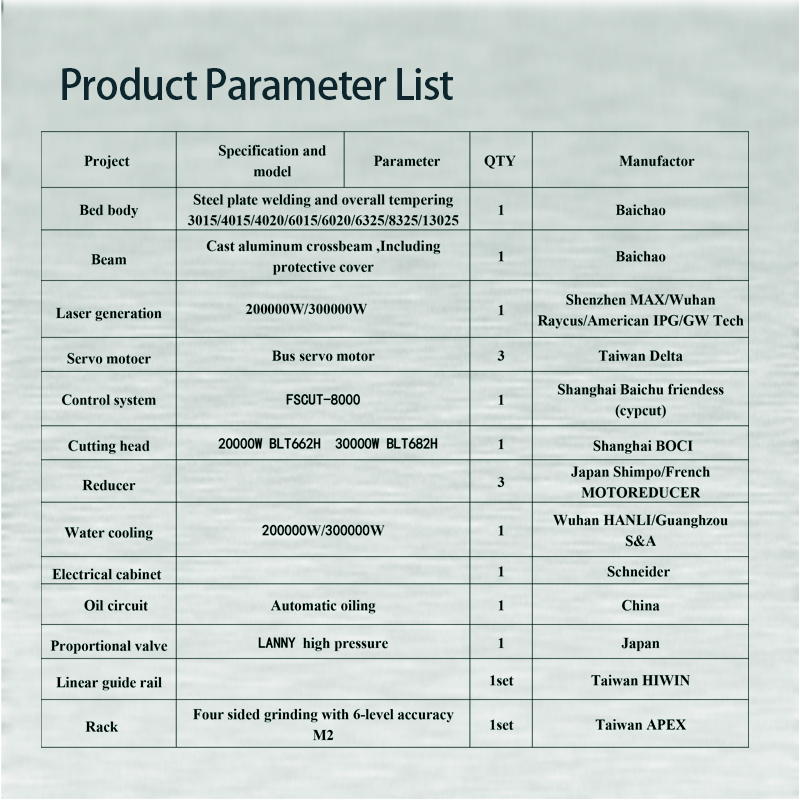

1. Double servo motor drive. 2. It has higher stability, higher speed and faster acceleration. 3. Full digital CNC servo motor communication. 4. The new peripheral design can enter the working area of the equipment from three different directions. 5. The machine adopts gantry structure, imported reducer and high-precision linear guide rail, with stable transmission and high precision, greatly improving the production efficiency of the machine tool. 6. The bed adopts the overall welding structure, rough machining after annealing, and then vibration aging treatment, which can completely eliminate the stress of welding and processing, with good rigidity, high precision and long-term use without deformation. 7. The crossbeam is integrally cast with aluminum alloy, rough processed after twice high temperature annealing, and then vibrated for aging. After high precision processing, it has good rigidity, light weight and dynamic performance. 8. Imported high-precision electric control proportional valve, precisely control the air pressure of cutting auxiliary gas to achieve the best cutting effect. It is much more accurate and convenient than the manual pressure regulating valve.